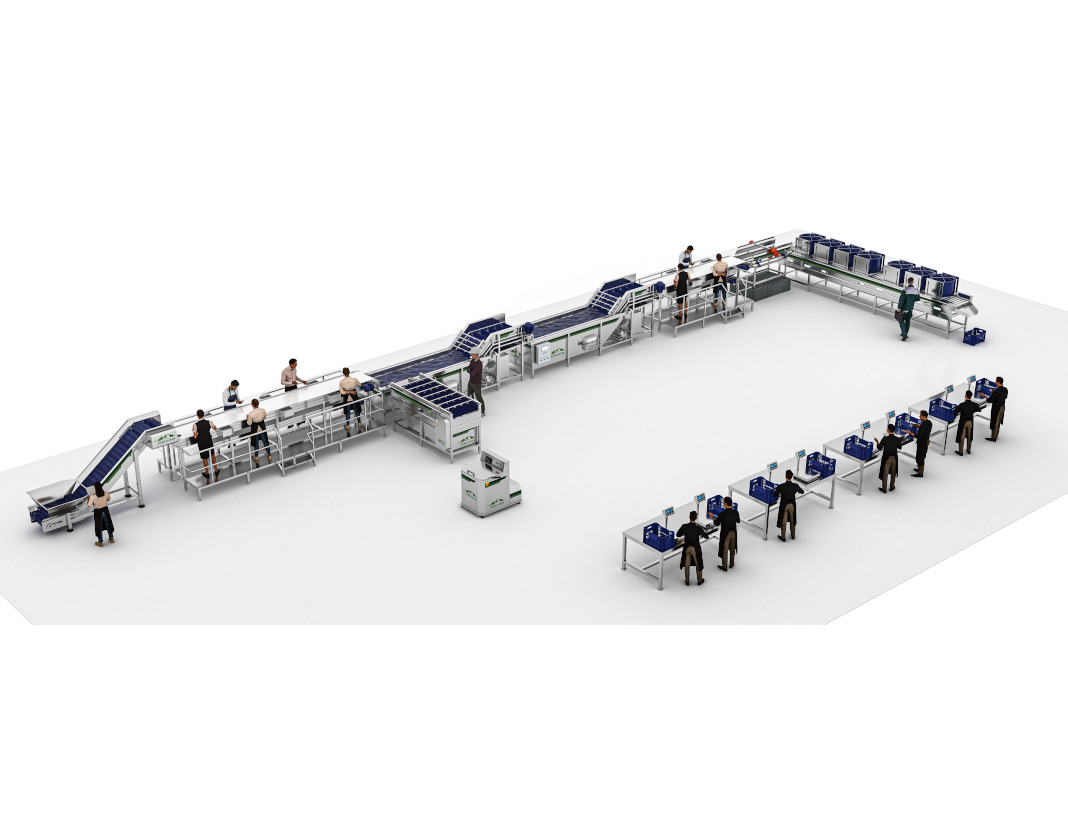

Processing Line

Fruits and vegetables still have a large amount of field heat after picking. This heat guides the rapid growth of critical growth of plants, and this heat is also combined with the release of trace elements in the water exposed by mechanical wounds left during the picking or processing of vegetables and fruits. It accelerates the discoloration of fruits and vegetables, and more closely matches the surface water of fruits and vegetables to nourish a large number of fungi and rapidly decay the body of fruits and vegetables.

Regardless of the type of fruit or vegetable, the crucial step in preserving freshness is to quickly and evenly eliminate the heat in the field, which is what we usually call pre-cooling. The first time to complete the pre-cooling has also laid a solid foundation for the preservation of fruits and vegetables. Evidently, light pre-cooling is not enough. The excess water on the surface of fruits and vegetables is an important root of nourishing fungi. Fruit and vegetable mechanical wounds are the accelerating areas of fruit and vegetable discoloration. Picking the fruits and vegetables continue to grow is the root cause of the aging of fruits and vegetables.

The processing line consists of below treatment

Cold Water Washing Treatment (up to 2°C)

Cold Water Washing will ensure larvae and eggs inside the green chilis are obliterated along with increasing the shelf life of green chilis by reducing inside and outside temperature of the green chilis.

Ozone Infused Water Washing Treatment (up to 2°C)

The use of ozone in food processing was affirmed as generally recognized as safe (GRAS) in May 1997 (EPRI, 1997; Graham, 1997) and approved by the U.S. Food and Drug Administration (FDA) as an antimicrobial agent for direct contact with all food types in June 2001 (FDA, 2001). Subsequently, numerous processes have been developed and adopted (EPRI, 2001; Sopher et al., 2002). When properly applied, ozone has the unique ability to kill microorganisms, avoid creation of mutants, and leave no harmful residual chemicals.

What is Ozone?

Ozone is a highly reactive and unstable form of oxygen. Ozone is made up of three oxygen atoms together, written as O3. It is called activated tri-atomic oxygen. It is a gas and is denser than air. Ozone is the second most powerful sterilizer in the world and its function is to destroy bacteria, viruses and odors.

How is Ozone applied to Water?

The ozone generator supply line interfaces with the process water supply or return line at a Venturi-type injection disperser unit. Adequate mixing and sensitive process monitoring is used for uniform treatment with the low concentrations applied to water for postharvest uses.

Common Organism killed by Ozone

Bacteria, fungus & mold spores, protozoa, fungal pathogens, virus, yeast, cysts and algae.

Benefits of Ozone Infused Water Treatment

- More effective than chlorine in destroying viruses and bacteria

- Utilizes a short contact time

- No harmful residuals that need to be removed after ozonation because ozone decomposes rapidly

- No regrowth of microorganisms, except for those protected by the particulates in the wastewater stream

- Generated onsite, and thus, there are fewer safety problems associated with shipping and handling

- Elevates the dissolved oxygen (DO)

- Saves money by eliminating on-going chemical costs

- Destroys all bacteria without a preference to one type of organism.

Common Organism killed by Ozone

Bacteria, fungus & mold spores, protozoa, fungal pathogens, virus, yeast, cysts and algae.

Benefits of Ozone Infused Water Treatment

- More effective than chlorine in destroying viruses and bacteria

- Utilizes a short contact time

- No harmful residuals that need to be removed after ozonation because ozone decomposes rapidly

- No regrowth of microorganisms, except for those protected by the particulates in the wastewater stream

- Generated onsite, and thus, there are fewer safety problems associated with shipping and handling

- Elevates the dissolved oxygen (DO)

- Saves money by eliminating on-going chemical costs

- Destroys all bacteria without a preference to one type of organism.

How does Ozone compare to Chlorine?

Ozone is reported to have 1.5 times the oxidizing potential of chlorine and 3,000 times the potential of hypochlorous acid (HOCl). Contact times for antimicrobial action are typically 4-5 times less than chlorine. Ozone rapidly attacks bacterial cell walls and is more effective against the thick-walled spores of plant pathogens and animal parasites than chlorine, at practical and safe concentrations. In comparison to the potential negative effects of residues and organic reaction products formed with chlorine applications, ozone has no reported deleterious byproducts. Oxidized products and oxygen are the outcome of ozone action.

Has ozone been tried for other postharvest uses?

Ozone has been evaluated for postharvest disease control and other storage uses for many years.

Background Articles on Ozone Infused Water Treatment

- Graham, Dee M. 1997. Use of ozone in food processing. Food Technol. 51(6): 72–75.

- EPRI (Electric Power Research Institute). 1992. Ozonation of cooling tower water in food processing. EPRI Technical Assessment vol. 4, no. 4.

- EPRI (Electric Power Research Institute). 1997. Prepared by:R and D Enterprises, Walnut Creek, CA, Expert Panel Report: Evaluation of the History and Safety of Ozone in Processing Foods for Human Consumption. EPRI Technical Report 108026 Vols. 1, 2, and 3.

- EPRI (Electric Power Research Institute). 2001. The use of ozone as an antimicrobial agent: agricultural and food processing technical assessment. EPRI TR-1005962.

- FDA (U.S. Food and Drug Administration). 2001. Secondary direct food additives permitted in food for human consumption, Fed. Reg. 66(123): 33829–33830.

- Kim, J.G. and Yousef, A.E. 2000. Inactivation kinetics of foodborne spoilage and pathogenic bacteria by ozone, in Journal of Food Science, Vol. 65, No. 3, p. 521-528.

- Use of ozone for food processing. Food Technology. 51: 72-75 Hunt, N K; Marinas, B J. 1997. Kinetics of Escherichia coli inactivation with ozone. Water Research 31:1355-1362.

- Joret, J C; Mennecart, V; Robert, C; Compagnon, B; Cervantes, P. 1997. Inactivation of indigenous bacteria in water by ozone and chlorine. Water Science and Technology 35: 8

- Liew, C L; Prange, R K. 1994. Effect of ozone and storage temperature on postharvest diseases and physiology of carrots (Daucus carota L.). Journal of the American Society for Horticultural Science 119: 563-567.

- Richardson, S.D., et.al. 1998.Chemical byproducts of chlorine and alternative disinfectants. Food Technology. 52:58-61

- Sarig, P; Zahavi, T; Zutkhi, Y; Yannai, S; Lisker, N; Ben-Arie, R. 1996. Ozone for control of postharvest decay of table grapes caused by Rhizopus stolonifer. Physiological and Molecular Plant Pathology 48: 403-415.